Pipeline Welding Inspection: Protecting Pipelines with Precision and Know-how

Pipeline Welding Inspection: Protecting Pipelines with Precision and Know-how

Blog Article

Best Practices for Pipe Welding Evaluation: Techniques, Requirements, and Procedures to Achieve Quality Control and Compliance

Reliable pipe welding evaluation is crucial for guaranteeing the honesty and safety of essential facilities. By using a mix of techniques such as aesthetic examination and advanced non-destructive screening approaches, along with adherence to established sector criteria like those from ASME and AWS, organizations can substantially enhance their high quality guarantee procedures. Nonetheless, the execution of these finest techniques poses numerous difficulties that warrant cautious consideration. Comprehending the intricacies included in each phase of assessment is crucial to achieving compliance and reliability in pipe systems. What specific methods can be employed to browse these difficulties effectively?

Relevance of Welding Inspection

The integrity of bonded joints is paramount in guaranteeing the safety and dependability of pipeline systems. Appropriate welding methods and detailed evaluation processes are essential to avoid failings that can bring about catastrophic incidents, environmental damages, and loss of life. Pipeline Welding Inspection. Welding assessment acts as a safety net, recognizing issues such as fractures, porosity, and incomplete combination prior to they intensify into major issues

In addition, pipeline systems typically operate under high stress and severe conditions, making the high quality of welds a lot more critical. Regulative compliance is an additional considerable aspect, as different standards determine the top quality assurance procedures that should be stuck to in pipe construction and upkeep. Failing to comply can lead to lawful implications and economic losses.

The function of welding examination expands past plain verification of craftsmanship; it includes the guarantee of lasting functional honesty. This includes a methodical method that consists of not just aesthetic evaluations however additionally progressed non-destructive screening approaches. Eventually, efficient welding assessment is an investment in the durability and security of pipe systems, ensuring they function as intended while reducing risks linked with product shortages.

Trick Evaluation Techniques

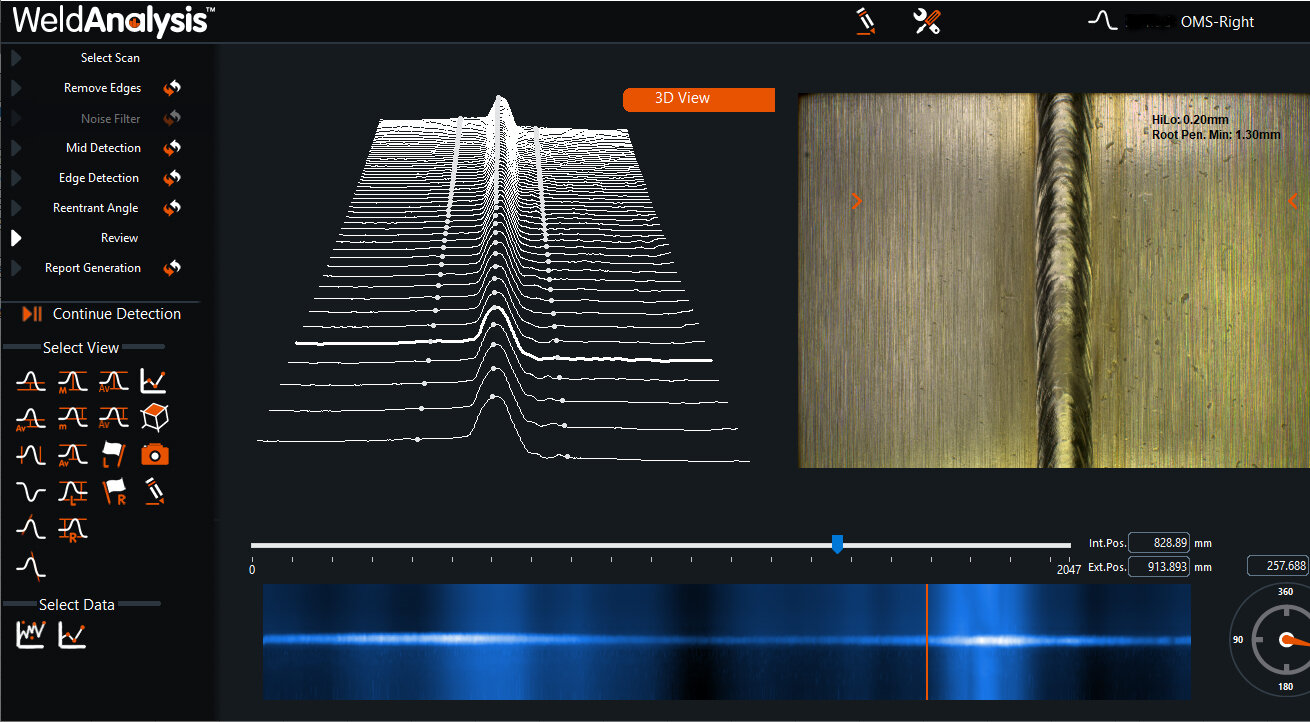

Aesthetic assessment, usually the initial line of protection, enables for the recognition of surface area problems such as splits, damages, and porosity. Ultrasonic testing utilizes high-frequency sound waves to identify interior defects, offering a comprehensive analysis of weld integrity. This non-destructive approach is specifically effective for identifying gaps that might not show up externally.

Radiographic screening entails using X-rays or gamma rays to produce pictures of the bonded joint, exposing internal flaws. This technique supplies thorough insights but might call for customized devices and safety considerations. Finally, magnetic fragment testing is efficient for finding surface and near-surface suspensions in ferromagnetic materials, using electromagnetic fields and fine iron fragments.

Industry Criteria and Laws

Conformity with industry standards and policies is important for ensuring the quality and security of pipe welding examinations. These standards supply a framework for ideal practices in welding processes, materials, and inspection strategies, permitting organizations to decrease issues and enhance the honesty of pipe systems. Secret bodies such as the American Culture of Mechanical Designers (ASME), the American Welding Society (AWS), and the International Company for Standardization (ISO) collection forth guidelines that are extensively identified and adopted within the industry.

In the United States, regulations from the Pipeline and Hazardous Products Security Administration (PHMSA) control the safety and security of pipeline operations, mandating extensive assessment methods. These standards not just offer to safeguard public security and the environment yet also guarantee conformity with lawful and legal commitments. Adherence to the pertinent codes, such as ASME B31.3 for procedure piping, is vital for keeping functional performance and governing compliance.

Additionally, continuous updates and revisions to these requirements mirror technical innovations and developing industry practices, stressing the requirement for companies to stay enlightened and train workers appropriately. Ultimately, durable compliance with well established requirements promotes trust and reliability in pipe framework, protecting both stakeholders and properties.

Reliable Evaluation Procedures

Efficient evaluation procedures are critical for identifying prospective defects in pipeline welds and making certain the total honesty of the system. A systematic strategy to examination includes numerous crucial phases, including pre-weld, in-process, and post-weld inspections. Each stage plays a vital function in maintaining quality control.

Throughout pre-weld assessment, it is necessary to examine the materials and joint setups, ensuring compliance with job specifications. In-process evaluations include checking welding methods and specifications, such as warmth input and travel rate, to stop defects from taking place. This stage enables real-time changes to welding techniques.

Post-weld examinations consist of non-destructive testing (NDT) methods like radiography, ultrasonic screening, and magnetic bit screening. These approaches help discover internal and surface area flaws that might endanger the pipe's performance. Documents of all assessment tasks is critical, providing a traceable useful site record that sustains compliance with market criteria.

Training and qualification of inspection personnel even more boost the effectiveness of original site these treatments. By adhering to a structured evaluation protocol, companies can mitigate threats, guarantee compliance, and ultimately provide pipes that satisfy stringent security and performance demands.

Common Obstacles and Solutions

Pipeline welding examination offers a number of common obstacles that can affect the quality and security of the end product. One significant difficulty is the variability in welding strategies and materials, which can lead to inconsistent weld high quality. To address this, it is crucial to establish standard procedures and training for welders, making sure an uniform method across projects.

Ecological elements, consisting of temperature and moisture, can likewise affect the welding process, potentially leading to fractures or incomplete fusion. Implementing controlled environments and sticking to pre-weld treatments can minimize these dangers.

Verdict

In final thought, the execution of ideal techniques for pipeline welding examination is essential for making certain quality guarantee and compliance with market criteria. A comprehensive approach, integrating different strategies such as visual, ultrasonic, and radiographic screening, promotes the recognition of issues throughout all stages of the welding process. Pipeline Welding Inspection. Adherence to established laws and efficient inspection treatments not just improves the reliability and safety and security of pipeline systems but also mitigates risks connected with welding flaws, thereby advertising general functional honesty

Compliance with sector standards and policies is essential for ensuring the quality and safety and security of pipe welding evaluations. These standards give a framework for finest techniques in welding processes, materials, and try this web-site inspection methods, permitting organizations to lessen flaws and enhance the stability of pipeline systems.In the United States, laws from the Pipe and Hazardous Products Safety And Security Management (PHMSA) govern the security of pipe operations, mandating strenuous evaluation methods. A methodical technique to examination includes numerous crucial stages, including pre-weld, in-process, and post-weld examinations.In final thought, the implementation of finest techniques for pipe welding assessment is vital for making certain high quality assurance and compliance with sector standards.

Report this page